The aerospace marketplace requires resources that stability toughness, fat, and efficiency less than Extraordinary ailments. Rifeng PMI Foam, crafted by among the leading PMI foam brands, provides a slicing-edge Resolution tailored for these complicated needs. Its exceptional Homes allow it to be a essential materials in the construction of plane, helicopters, and also other advanced aerospace elements. This blog site explores the special great things about Rifeng PMI Foam and its apps in aerospace engineering.

Table of contents:

Enhancing plane Structural Integrity with Rifeng PMI Foam

light-weight answers: lowering pounds devoid of Compromising Strength

Thermal Stability of Rifeng PMI Foam in higher-Temperature Environments

scenario scientific tests: thriving Integration of Rifeng PMI Foam in Aerospace

improving plane Structural Integrity with Rifeng PMI Foam

Structural integrity is actually a cornerstone of aerospace style, and Rifeng PMI Foam sets a new normal During this vital spot. With its Fantastic energy-to-weight ratio, it provides The perfect foundation for generating strong composite buildings whilst preserving durability less than superior stress and demanding circumstances. This Superior foam don't just enhances stiffness and effects resistance but also minimizes bodyweight, which happens to be important for achieving ideal efficiency in aerospace applications. Its versatility can make it a perfect choice for structural panels, aircraft radomes, along with other crucial factors exactly where toughness and dependability are non-negotiable. Engineers count on its mechanical energy to make certain safety and efficiency, even in higher-stakes, substantial-functionality environments for instance helicopter blades, unmanned aerial motor vehicles (UAVs), together with other cutting-edge aerospace systems. Rifeng PMI Foam is usually a dependable Answer for pushing aviation and aerospace innovation to new heights.

light-weight options: lessening excess weight with no Compromising power

Reducing fat is important in aerospace to boost gas efficiency, All round general performance, and sustainability. Rifeng PMI Foam is especially engineered with a high-quality mobile structure that minimizes resin absorption throughout core shaping, causing significantly lighter ultimate factors. This State-of-the-art style not just decreases product body weight but also cuts down on resin usage, additional contributing towards the effectiveness of creation procedures. The exclusive characteristics of this foam produce reduced operational prices, diminished environmental influence, and improved Power efficiency, which makes it a perfect Alternative to the aerospace field. Irrespective of its lightweight character, Rifeng PMI Foam would not compromise about the mechanical Homes of the material, ensuring toughness and dependability in demanding programs. By providing an optimum harmony of performance and minimum body weight, Rifeng PMI Foam has grown to be a trustworthy option for companies looking for modern, Price-helpful, and sustainable solutions for contemporary aerospace troubles.

Thermal steadiness of Rifeng PMI Foam in higher-Temperature Environments

Aerospace factors are intended to resist Severe environmental problems, such as rigorous mechanical strain and large temperatures. Rifeng PMI Foam stands out with its exceptional thermal resistance, keeping security and responsible overall performance even though exposed to curing temperatures of up to one hundred eighty°C right after right procedure. This Innovative ability assures its success in demanding production processes for instance vacuum infusion (VARI) and resin transfer molding (RTM), wherever thermal endurance is critical. Its extraordinary thermal stability and sturdiness provide engineers with The boldness to employ it in warmth-crucial and high-overall performance programs, which includes radome plane, aerospace interiors, and advanced structural composites. Rifeng PMI Foam not just boosts substance overall performance but additionally contributes on the longevity and safety of aerospace parts less than complicated conditions.

situation research: Successful Integration of Rifeng PMI Foam in Aerospace

Rifeng PMI Foam’s progressive abilities have already been productively applied in several aerospace tasks, showcasing its versatility and value in substantial-efficiency programs. For example, its light-weight nonetheless strong Attributes have revolutionized helicopter blade manufacturing, substantially lessening All round rotor excess weight when boosting toughness and operational performance. This not simply increases flight functionality but will also helps decrease gas consumption and servicing demands eventually. likewise, UAV (Unmanned Aerial car) designers have enormously benefited through the foam’s minimal resin absorption, that makes the producing approach far more productive, and its extraordinary mechanical energy, which reinforces flight performance and Total structural integrity, even under demanding situations. Furthermore, the material has tested indispensable in the manufacture of radomes, exactly where its stiffness and Excellent bonding Attributes guarantee reputable functionality, even in Serious environmental circumstances for instance large winds, temperature fluctuations, and humidity. These traits make Rifeng PMI Foam a significant element in advancing reducing-edge aerospace technological know-how.

In summary, the flexibility and general performance of the Highly developed foam materials have made it an indispensable asset across many aerospace applications. Its unique mix of toughness, light-weight design and style, and durability proceeds to drive pvc foam manufacturers the boundaries of innovation, enabling engineers to meet the demanding difficulties of modern aviation and beyond. With its demonstrated reputation, this material is about to remain a important ingredient in future developments inside the aerospace industry.

Alisan Porter Then & Now!

Alisan Porter Then & Now! Jeremy Miller Then & Now!

Jeremy Miller Then & Now! Kenan Thompson Then & Now!

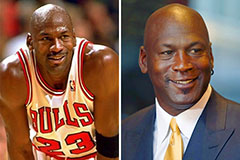

Kenan Thompson Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now! Daryl Hannah Then & Now!

Daryl Hannah Then & Now!